Bachem automates SPPS

Submitted by:

Andrew Warmington

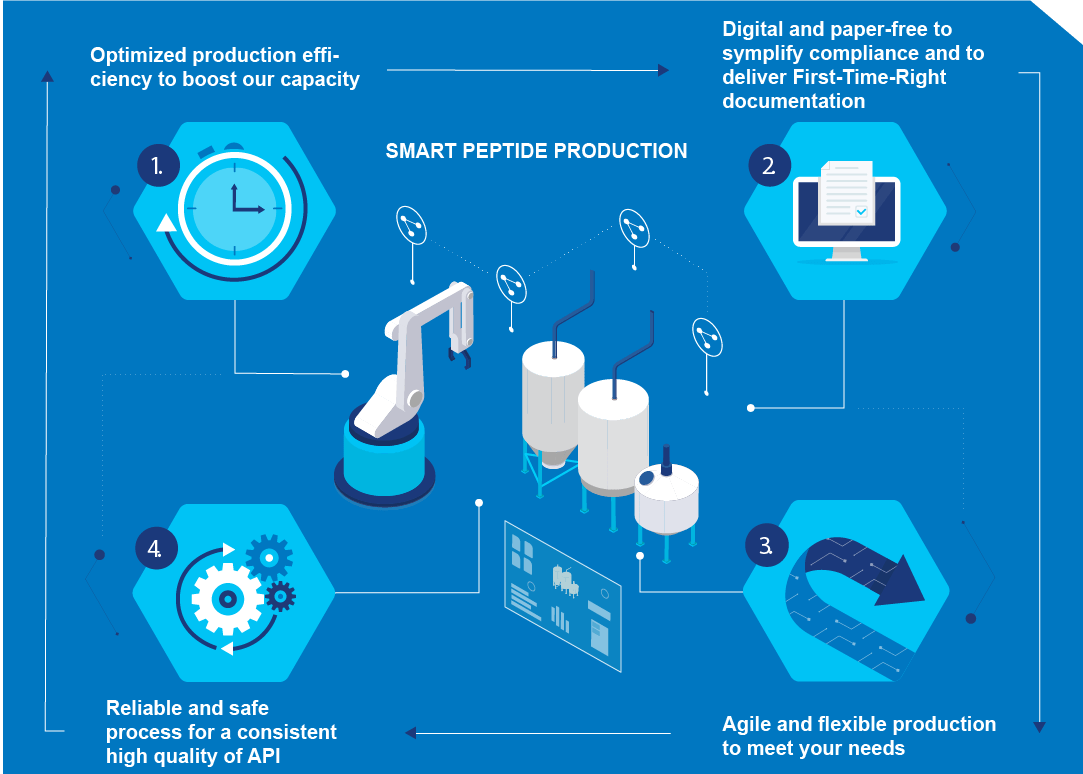

Bachem, the world market leader in peptides, has automated and digitalised one of its core business processes, solid-phase peptide synthesis (SPPS). The company describes this as the start of its journey to Industry 4.0. The process is described in detail on the company website (www.bachem.com/news/bachem-journey-to-industry-4-0/).

This, Bachem said, that means that “operations can be carried out with minimal human intervention, thus improving the reliability of the process, reproducibility of results and safety, while significantly increasing the cost-effectiveness of operations”. Equipment utilisation will be optimised, while operating and personnel times will be reduced “down to a fraction”, such that new projects can be taken on.

Bachem has also invested in the digitalisation of the production process so that documentation can be conducted paper-free. “Furthermore, we can attain improved first-time-right rates, data analytics by implementing a plant information system, and higher data safety and integrity,” the company stated.

Other steps towards automating commercial-scale SPPS include the first Bachem robot-operator, BALU. This handles the containers with the amino acid powders and transfer powder into the activator vessels for 150L SPPS reactors, without any operator involvement. It can also clean the amino acid transfer port to prevent cross-contamination.

The automated SPPS process also features process analytical technology, which performs inline analytics after key steps. This removes the need for manual in-process controls and provides a better control of critical process parameters, Bachem stated. It also reduces the need for operator involvement and leads to higher reproducibility with minimised chemical side reactions.