Feature article - How process experts are accelerating digitalisation: The rise of citizen development

Submitted by:

Andrew Warmington

John Papastylianou, CEO and managing director of Cyzag, looks at how citizen development is helping to speed the uptake of AI in the industry

Recent analyses of the European chemical sector highlight a continuing decline in competitiveness. Capacity utilisation remains below pre-pandemic levels; energy costs are high, and capital investment remains cautious. Producers are under growing pressure to improve efficiency, adaptability and resource use within existing assets.

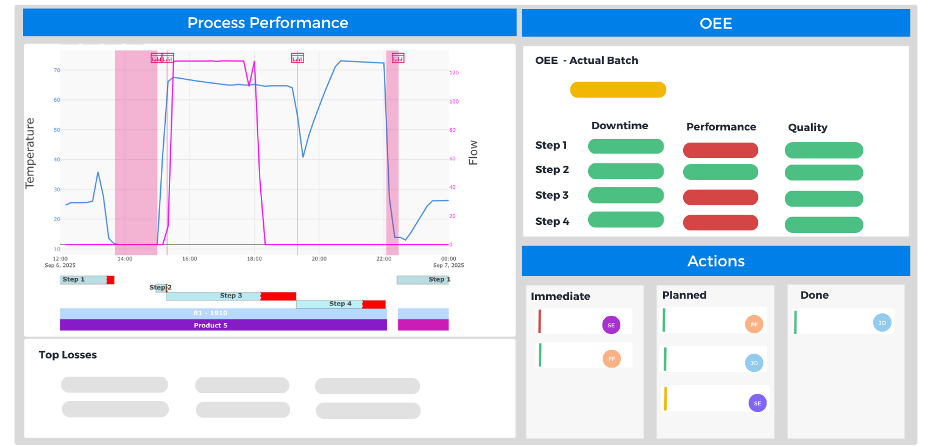

Achieving these goals requires greater visibility and responsiveness at plant level: the ability to understand what is happening in real time, act faster on deviations, and continuously optimise energy, yield and quality performance. Digitalising daily operations is becoming an effective way to do so, moving improvement decisions from periodic reviews to daily execution.

A practical response to structural challenges

It is no longer realistic for digitalisation to remain confined to a single IT department. The scale and speed of transformation now require a more distributed model that enables technical and operational experts to create and refine their own tools.

Using low-code and no-code platforms, enables engineers and technical operators to develop and deliver use cases to operations that track performance, standardise workflows, or monitor energy and material use. Digitalisation is most effective when it empowers those closest to the process to improve it.

A shift in how digitalisation happens

These initiatives are led by so-called citizen developers, non-IT professionals who use visual interfaces to build use cases, automate data flows, and create workflow applications. Found mainly within production or technical departments, they combine process knowledge with digital tools to address issues as they arise, ensuring solutions remain directly relevant to plant operations.

To sustain this model, many organisations are cultivating what are known as ‘purple’ skills, a blend of the ‘blue’ strengths of IT (data, architecture, and governance) with the ‘red’ strengths of operations (process knowledge and improvement culture). These hybrid professionals act as translators between digital and operational domains, ensuring locally built tools are secure, compliant and aligned with enterprise systems.

As AI becomes increasingly embedded in low-code platforms, these capabilities will be essential to capture tribal knowledge and ensure it enhances daily work rather than complicating it.

Operational advantages

When supported by clear governance, citizen development strengthens process execution and decision support. Typical benefits include:

- Fit-for-purpose solutions built around real production needs

- Shorter development cycles measured in days or weeks

- Knowledge capture and continuity of local expertise

- Higher engagement and ownership among frontline teams

- Reduced reliance on external contractors

- Unified operational view through a single window, integrating data and workflows

- Replicable improvements adaptable across sites

Beyond an operational advantage, this last point, replicability, represents a strategic differentiator for manufacturers. Many organisations are now templatising successful use cases and best practices across plants, allowing proven use cases to be shared and scaled with minimal effort.

This ensures consistency, accelerates value capture and prevents the fragmentation often caused by isolated, single-point solutions. It provides a clear path to scale operational excellence across the network, turning local improvements into enterprise-wide transformation.

Governance & application in practice

Empowering non-IT professionals to create digital tools brings speed but also potential risks, such as inconsistent data or fragmented workflows. To manage this effectively, many manufacturers adopt structured enablement models that define clear roles, access boundaries, and review procedures.

A multinational manufacturer in the speciality chemicals sector deployed a no-code platform across multiple sites. Process engineers and operators developed modules for shift handovers, deviation tracking, and energy monitoring, all linked with process data. The applications reduced administrative effort, improved communication between shifts and supported faster identification of deviations. Energy-tracking use cases helped save approximately €150,000/year through improved steam-loss detection in a single plant.

The road ahead

Citizen development marks a practical shift in how digital transformation unfolds in manufacturing. By giving process experts, the tools to act on data, companies can respond faster, operate more efficiently and build greater resilience for the challenges ahead.

Contact

John Papastylianou

CEO & Managing Director

Cyzag